ZLD Drying System

ZLD Drying System, Final Step in Zero Liquid Discharge for Complete Wastewater Solidification

The Zero Liquid Discharge (ZLD) Drying System is engineered to solidify concentrated brine or slurry into dry solids, ensuring complete elimination of liquid waste. As the concluding phase in the ZLD process, it transforms residual moisture into manageable solids, facilitating easier disposal or resource recovery.

Key Features & Advantages

- Comprehensive Moisture Removal: Achieves final moisture content levels as low as 5%, ensuring compliance with stringent environmental regulations

- Energy-Efficient Operation: Optimized drying technologies minimize energy consumption while maximizing throughput

- Versatile Handling: Capable of processing various feed types, including high-viscosity slurries and crystallized salts

- Compact Modular Design: Skid-mounted systems allow for easy installation, scalability, and transportation

- Automated Control Systems: Advanced controls ensure consistent performance and reduce the need for manual intervention

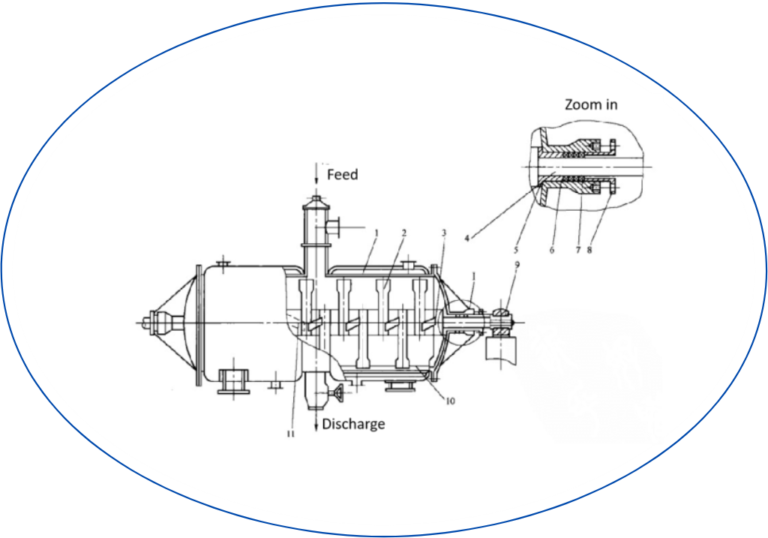

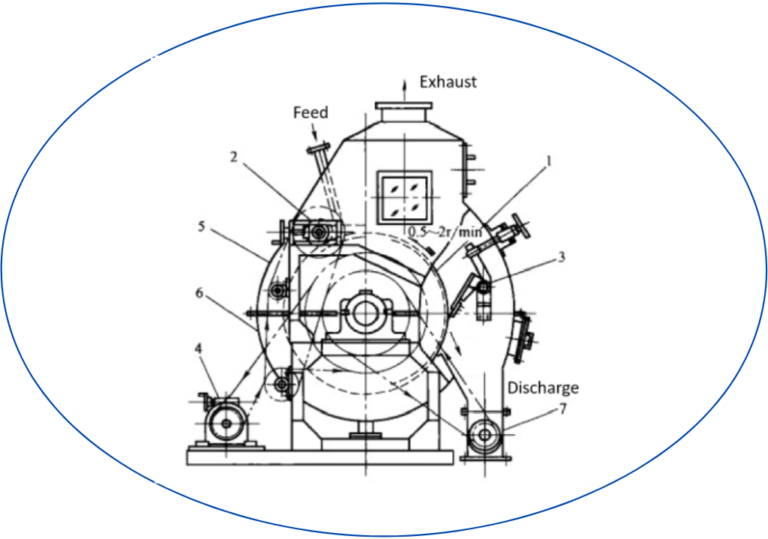

System Components

- Drying Unit – Removes residual moisture from concentrated feed material

- Heat Source – Provides thermal energy to drive the drying process

- Dust Collection System – Captures fine particles and ensures clean, safe operation

- Conveying Mechanism – Transfers dried solids to storage or further handling

- Control Panel – Centralized system monitoring and automation

Applications

- Industrial Wastewater Treatment: Solidification of concentrated brine from various industrial processes

- Chemical Manufacturing: Drying of chemical slurries and crystallized compounds

- Mining and Metallurgy: Processing of mineral-rich tailings and sludges

- Power Generation: Treatment of flue gas desulfurization (FGD) wastewater

- Food and Beverage Industry: Drying of waste by-products for reduced disposal volume

Engineering, Manufacturing & Integration Support

Hydrodyna, in collaboration with Sanfeng, offers comprehensive turnkey solutions encompassing design, manufacturing, testing, and delivery. Each ZLD Drying System is engineered for operational efficiency and ease of deployment, emphasizing modularity and adherence to international standards.

- Custom Design & Manufacturing: Tailored systems to meet process-specific needs and material characteristics

- Skid-Mounted Modular Systems: Pre-assembled units simplify installation and are easily transported

- Factory Acceptance Testing (FAT): Full testing conducted before shipment to ensure optimal function

- Site Acceptance Testing (SAT): On-site commissioning and performance validation

- 3D Modeling & Documentation: Complete technical support through detailed drawings and operation manuals