MBR Operation & Maintenance

Membrane Bioreactors (MBRs) are a powerful wastewater treatment technology combining biological treatment with membrane filtration. While they offer superior effluent quality and a smaller footprint compared to conventional systems, optimal performance relies heavily on proper operation and maintenance (O&M). This post explores key O&M best practices to ensure long-term membrane health, energy efficiency, and minimized downtime.

![Operation and Maintenance Best Practices for MBR Systems 3 Factors affecting membrane fouling and treatment performance [1].](https://hydrodyna.com.au/wp-content/uploads/2025/03/4-4.png)

1. Maintain Stable Biological Conditions

A stable biological process is essential for membrane longevity and system efficiency.

- Target MLSS: Maintain Mixed Liquor Suspended Solids (MLSS) typically between 8,000–12,000 mg/L. Overloading can lead to fouling.

- SRT Control: Use long sludge retention times (20–30 days) to reduce sludge production and support nitrification.

- DO Monitoring: Ensure sufficient dissolved oxygen (>2 mg/L) in the bioreactor to support aerobic microbial activity and prevent fouling by filamentous bacteria.

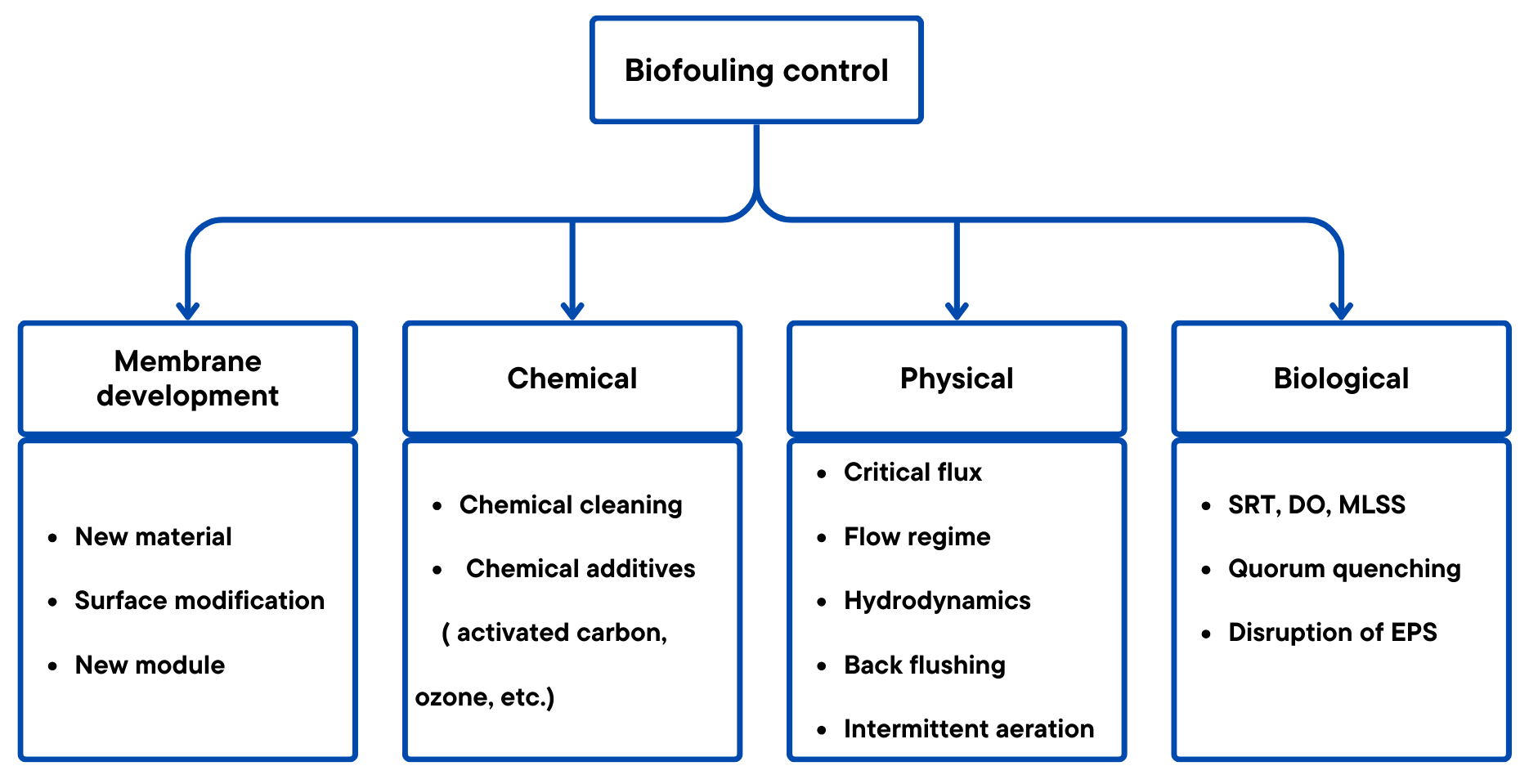

2. Proactive Membrane Fouling Management

Membrane fouling is the primary challenge in MBR systems. Routine prevention is more effective than reactive cleaning.

- Physical Cleaning (Relaxation and Backflushing): Follow manufacturer recommendations for relaxation intervals and air scouring.

- Chemical Cleaning: Perform regular Clean-In-Place (CIP) with hypochlorite or citric acid based on flux decline or TMP rise.

- Monitor Transmembrane Pressure (TMP): An increasing TMP trend is an early indicator of fouling.

3. Flux Optimization

Operating at appropriate flux (flow per membrane area) levels extends membrane life and improves energy efficiency.

- Design Flux: Stay within 15–30 L/(m².h) for municipal applications in i-MBRs (follow the recommendation by supplier). Always operate below critical flux which is the maximum flux below which a membrane can operate without experiencing significant or irreversible fouling [2].

- Adaptive Flux Control: Use flux stepping or automated control systems to adjust to influent variability.

4. Aeration Control for Membrane Scouring

Proper aeration not only supports biological processes but also controls fouling through membrane scouring.

- Intermittent Aeration: Use cyclic or pulse aeration to reduce energy while maintaining cleaning efficiency.

- Airflow Rate: Ensure scouring air rates are maintained per membrane supplier guidelines, typically 0.3–0.6 Nm³/h per m² of membrane [3].

5. Routine Monitoring and Data Logging

Establish a robust monitoring program to catch issues early.

- Key parameters to log:

- TMP (daily)

- Permeate flow and flux

- MLSS/MLVSS

- pH, DO, temperature

- Cleaning frequency and chemical usage

- Trend analysis of TMP and flux can reveal gradual fouling or equipment degradation.

6. Sludge Management and Waste Handling

MBR produces less sludge than CAS, but handling still requires attention.

- Waste Activated Sludge (WAS) withdrawal: Schedule regular wasting based on SRT and MLSS trends.

- Sludge thickening or dewatering: Coordinate with downstream handling systems for efficiency.

7. Emergency and Downtime Preparedness

Be prepared for unexpected issues like membrane damage, power loss, or sudden loading increases.

- Spare parts inventory: Keep critical spares like blower components, valves, and a few spare membrane cassettes.

- Bypass systems: Design and maintain emergency bypass or overflow routes.

8. Staff Training and Documentation

Trained operators are the backbone of reliable MBR operation.

- Regular training on biological process control, membrane maintenance, and troubleshooting.

- Maintain SOPs and cleaning logs for consistency and accountability.

Conclusion

Effective operation and maintenance of MBR systems hinges on a balance between biological process control and membrane care. By implementing proactive monitoring, cleaning, and optimization strategies, operators can extend membrane life, reduce energy and chemical use, and maintain consistent high-quality effluent.

References

- Membrane Biological Reactors – Edited by Faisal I. Hai, Kazuo Yamamoto, and Chung-Hak Lee

📖Chapter 2: Process Fundamentals: From Conventional Biological Wastewater Treatment to MBR

Authors: V. Jegatheesan & C. Visvanathan

📖 Chapter 4: Monitoring, characterization and control of membrane biofouling in MBR

Authors: Katsuki Kimura, Fangang Meng, In-Soung Chang and Chung-Hak Lee

- Metcalf & Eddy – Wastewater Engineering: Treatment and Resource Recovery (5th Edition)

📖Chapter 14: Membrane Biological Reactors - The MBR Book – Simon Judd

📖Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment

A comprehensive guide covering MBR fundamentals, design, operation, and case studies.