Freezing Separation System

Freezing Separation System, Innovative Low-Temperature Crystallization for High-Purity Separation

The Freezing Separation System is designed to process materials whose solubility significantly decreases with temperature reduction. By leveraging controlled freezing, this system facilitates the crystallization and separation of target compounds, offering an energy-efficient alternative to traditional thermal evaporation methods.

Key Features & Advantages

- Low-Temperature Operation: Reduces energy consumption and preserves the integrity of heat-sensitive materials.

- High Purity Output: Achieves superior separation quality, ideal for applications requiring high-purity end products.

- Scalable Design: Modular configuration allows for easy scaling to meet varying production capacities.

- Automated Control: Advanced control systems ensure precise temperature regulation and process stability.

- Reduced Scaling and Fouling: Lower operational temperatures minimize the risk of scaling, extending equipment lifespan

Applications

- Lithium Industry: Extraction and purification of lithium salts from brine solutions.

- Chemical Manufacturing: Separation of temperature-sensitive compounds requiring gentle processing conditions.

- Pharmaceuticals: Crystallization of active pharmaceutical ingredients (APIs) without thermal degradation.

- Food & Beverage: Concentration and purification of products like fruit juices and dairy without compromising quality.

- Environmental Engineering: Treatment of industrial effluents where traditional evaporation is not feasible.

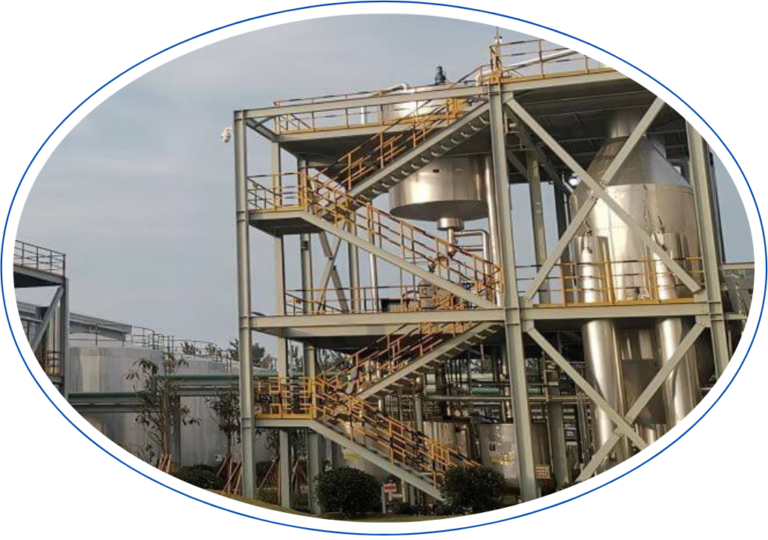

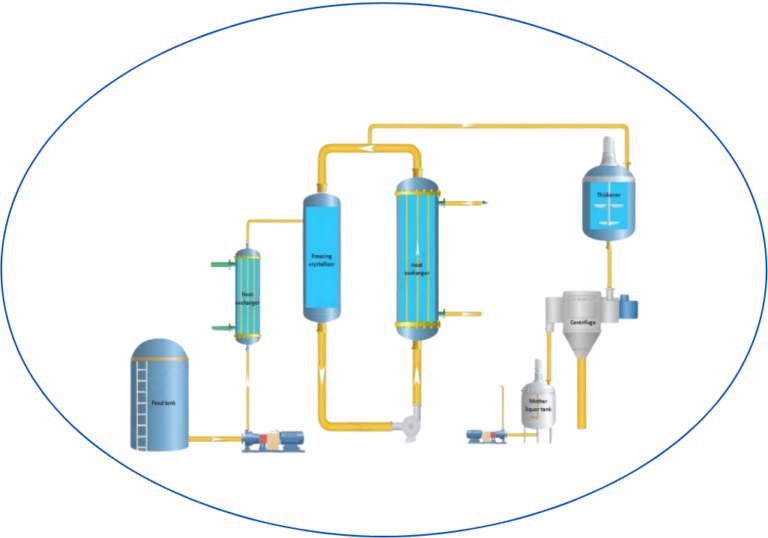

System Components

- Freezing Unit: Initiates controlled crystallization by lowering the temperature of the feed solution.

- Crystallizer: Facilitates the growth of crystals from the supersaturated solution.

- Separator: Separates the formed crystals from the remaining liquid phase.

- Circulation Pump: Maintains consistent flow and temperature distribution throughout the system.

- Control Panel: Monitors and regulates system parameters to ensure optimal performance.

Engineering, Manufacturing & Integration Support

Hydrodyna, in collaboration with Sanfeng, provides comprehensive services encompassing design, manufacturing, testing, and delivery. Each Freezing Separation System is engineered for efficiency and ease of deployment, with a focus on modularity and adherence to international standards.

- Custom Design & Manufacturing: Tailored solutions to meet specific process requirements and material characteristics.

- Skid-Mounted Modular Systems: Pre-assembled units for rapid installation and easy transportation.

- Factory Acceptance Testing (FAT): Comprehensive testing prior to shipment to ensure system performance and compliance.

- Site Acceptance Testing (SAT): On-site validation and commissioning support for seamless integration.

- 3D Modeling & Documentation: Detailed engineering drawings and manuals to facilitate installation and maintenance.