Multi-Effect Evaporation (MEE) System

Multi-Effect Evaporation (MEE) System, Efficient Thermal Evaporation for Industrial Applications

The Multi-Effect Evaporation (MEE) system is a highly efficient thermal process designed to concentrate liquid streams by utilizing the latent heat of vaporization across multiple stages. By reusing vapor energy from one effect to the next, MEE systems significantly reduce steam consumption, making them ideal for industries focused on sustainable and cost-effective operations.

Key Features & Advantages

- Energy Efficiency: Multiple-effect design recycles steam across stages, greatly reducing overall energy use.

- Flexible Configuration: Tailored designs ranging from double to quintuple effects, with options for forward, backward, or mixed feed.

- High Heat Transfer Rates: Short residence times and rapid heat exchange minimize thermal degradation.

- Low Fouling Design: Optimized to reduce scaling and extend cleaning intervals.

- Fully Automated Operation: Integrated PLC/SCADA systems enable stable and precise control.

Applications

- Zero Liquid Discharge (ZLD) Systems: Concentrates high TDS brines and minimizes final waste volume.

- Chemical Processing: Recovers and concentrates valuable chemicals while maintaining product quality.

- Food & Beverage Industry: Used for concentrating juice, dairy, syrup, and other heat-sensitive liquids.

- Pharmaceuticals: Supports solvent recovery and intermediate concentration with low thermal stress.

- Textile & Dyeing Plants: Efficiently removes dyes and chemicals from wastewater streams.

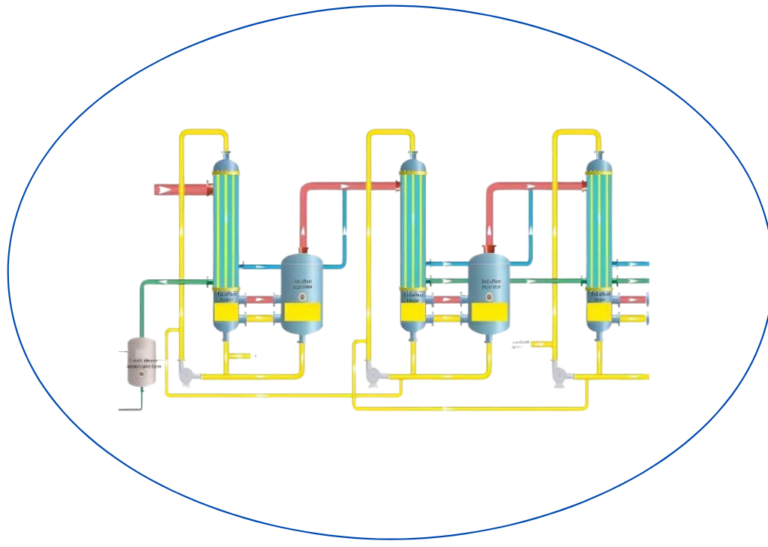

System Components

- Evaporator Heat Exchangers: Provide efficient thermal transfer across each effect.

- Vapor-Liquid Separators: Separate generated vapor from concentrated liquid at each stage.

- Circulation Pumps: Maintain flow consistency and optimal heat distribution.

- Vacuum System: Enables evaporation at lower temperatures for heat-sensitive fluids.

- Condenser Unit: Condenses final vapor into reusable or dischargeable water.

- Automated Control Panel: Centralized PLC system for real-time monitoring and operation.

Evaporator Types Available

- Falling Film Evaporator: Best for low-viscosity fluids and minimal scaling applications.

- Forced Circulation Evaporator: Ideal for high TDS, high COD wastewater and viscous materials.

Engineering, Manufacturing & Integration Support

Hydrodyna, in collaboration with Sanfeng, offers complete turnkey support — from system design to fabrication, testing, and delivery. Each system is engineered for operational efficiency and ease of deployment, with a strong focus on modularity and international project standards.

- Custom Design & Manufacturing: Sanfeng not only designs but also manufactures all systems in-house, ensuring quality control, material traceability, and performance assurance.

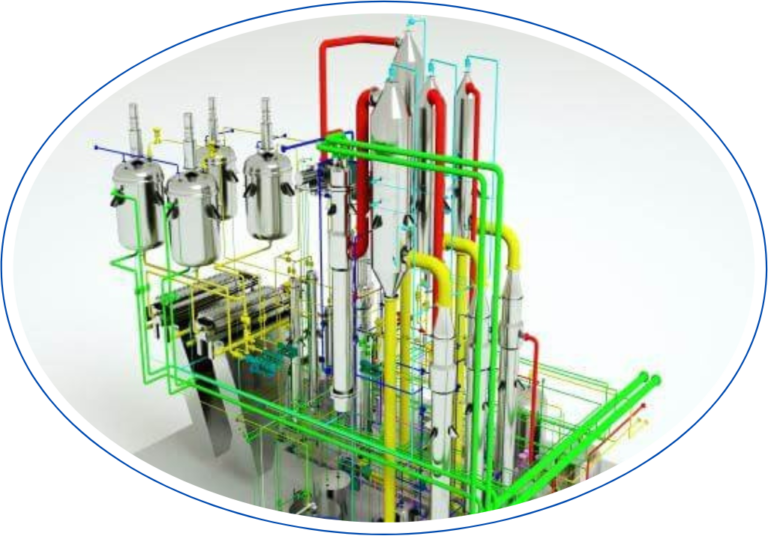

- Skid-Mounted Modular Systems: Units are pre-assembled on skids for rapid installation, easy disassembly, and containerized transport to sites across Australia and globally.

- Factory Acceptance Testing (FAT): Each unit undergoes thorough FAT prior to shipment to ensure performance, safety, and automation compliance.

- Site Acceptance Testing (SAT): On-site validation and commissioning support are provided to guarantee seamless system integration and operation.

- 3D Modeling & Documentation: Detailed engineering drawings, models, and technical manuals are provided to support installation, operation, and maintenance.