MVR Evaporation System

MVR Evaporation System, Advanced Energy-Efficient Solution for Industrial Evaporation Needs

The Mechanical Vapor Recompression (MVR) Evaporation System is an advanced thermal processing technology designed to minimize energy consumption by recycling the latent heat of vaporization. By compressing and reusing the secondary steam generated during evaporation, the MVR system significantly reduces the need for external steam, making it an ideal solution for industries aiming for sustainability and cost-effectiveness.

Key Features & Advantages

- High Energy Efficiency: Utilizes electrical energy to compress and recycle secondary steam, reducing external steam requirements and operational costs.

- Gentle Evaporation Process: Operates with smaller and more stable temperature differences, making it suitable for heat-sensitive materials and reducing the risk of scaling.

- Compact Design: Features a small footprint, leading to lower civil engineering costs and reduced consumption of supporting resources.

- Automated Operation: Equipped with a fully automatic control system for stable operation, minimizing the risk of human error.

- Low Maintenance: Simplified process flow and the option for Clean-In-Place (CIP) systems facilitate easy maintenance and cleaning.

Applications

- Zero Liquid Discharge (ZLD) Systems: Effectively concentrates brine and reduces wastewater volume, facilitating complete liquid waste elimination

- Chemical Processing: Ideal for concentrating and recovering valuable chemicals from process streams

- Food & Beverage Industry: Used for concentrating products like juice, milk, and other heat-sensitive liquids

- Pharmaceuticals: Supports solvent recovery and concentration processes, maintaining product integrity

- Textile & Dyeing Plants: Efficiently removes and recovers colorants and chemicals from wastewater

System Components

- MVR Steam Compressor – Compresses secondary steam to increase its temperature and pressure for reuse in the evaporation process

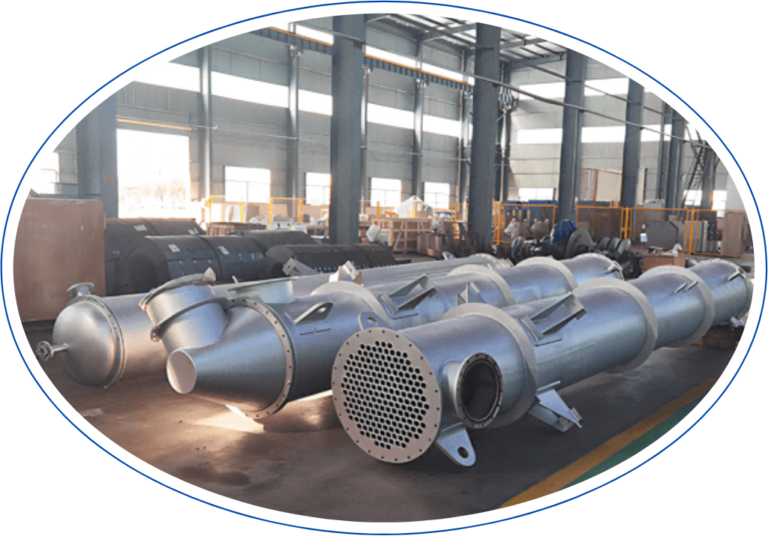

- Heat Exchanger (Evaporator) – Transfers heat to the feed solution, facilitating evaporation

- Separator (Crystallizer) – Separates vapor from the concentrated liquid

- Evaporative Circulation Pump – Maintains the circulation of the solution through the system

- Preheater – Preheats the feed solution to improve energy efficiency

- Auxiliary Tanks and Pumps – Support various functions within the system, such as condensate handling and chemical dosing

- Control System – Manages and monitors the operation of the entire system for optimal performance

Engineering, Manufacturing & Integration Support

Hydrodyna, in collaboration with Sanfeng, offers comprehensive turnkey solutions encompassing design, manufacturing, testing, and delivery. Each MVR system is engineered for operational efficiency and ease of deployment, emphasizing modularity and adherence to international standards.

- Custom Design & Manufacturing: Sanfeng designs and manufactures all systems in-house, ensuring quality control and performance assurance

- Skid-Mounted Modular Systems: Pre-assembled units facilitate rapid installation, easy disassembly, and containerized transport

- Factory Acceptance Testing (FAT): Each unit undergoes thorough testing before shipment to ensure performance and compliance

- Site Acceptance Testing (SAT): On-site validation and commissioning support guarantee seamless integration and operation

- 3D Modeling & Documentation: Detailed engineering drawings and technical manuals support installation and maintenance