Skid-Mounted Evaporator

Skid-Mounted Evaporator – Modular and Efficient Evaporation Solutions

Hydrodyna, in collaboration with Sanfeng, offers skid-mounted evaporators designed for rapid deployment and efficient operation. These modular systems are pre-assembled on a skid, facilitating easy transportation, installation, and integration into existing processes. Ideal for industries seeking flexible and scalable evaporation solutions, skid-mounted evaporators are particularly suited for applications requiring Zero Liquid Discharge (ZLD) and high-efficiency concentration.

Key Features & Advantages

- Modular Design – Pre-assembled units minimize on-site installation time and complexity

- Compact Footprint – Space-saving design allows for installation in facilities with limited space

- Scalable Capacity – Available in 0.5 TPH, 1 TPH, 1.5 TPH, and 2 TPH models

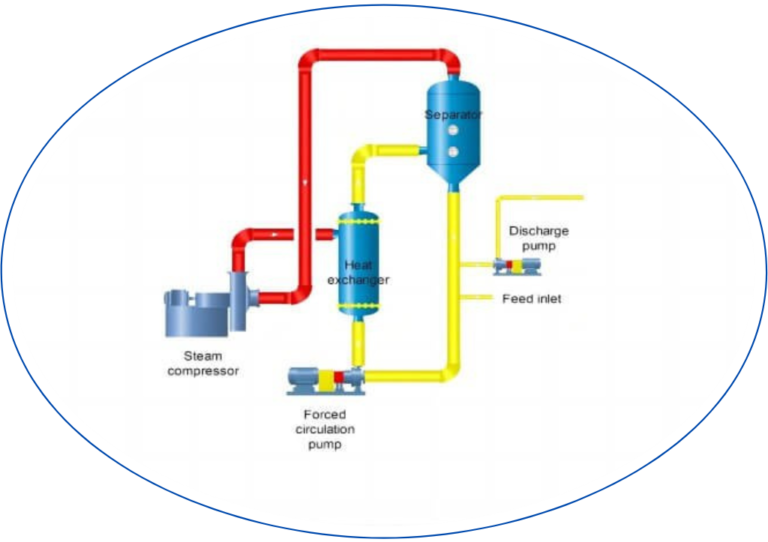

- Energy Efficiency – Incorporates Mechanical Vapor Recompression (MVR) to significantly reduce energy use

- Easy Utility Integration – Connects seamlessly to steam, electricity, compressed air, tap water, and cooling water

- Optional Add-Ons – Additional modules available: hardness removal, electric steam generator, air compressor, and cooling tower

Applications

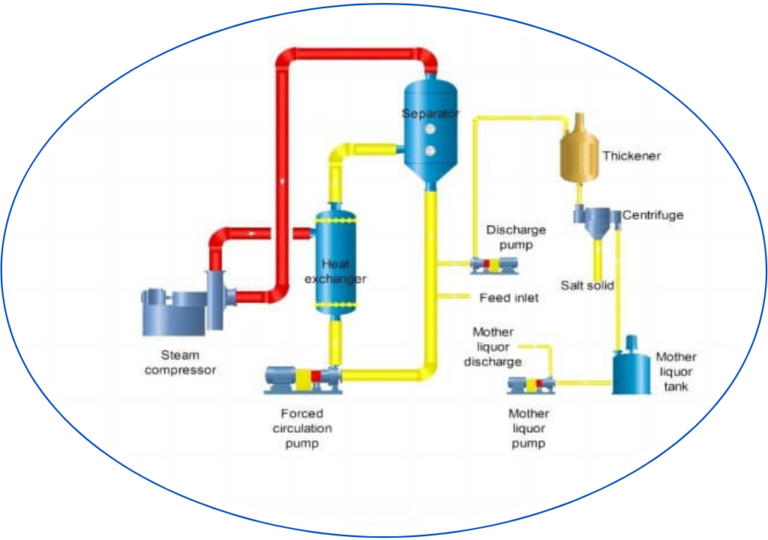

- Zero Liquid Discharge (ZLD) Systems: Enables modular and efficient concentration and crystallization of high TDS wastewater streams, supporting compliance with ZLD regulations.

- Chemical Processing: Suitable for the concentration and recovery of valuable chemical compounds in both batch and continuous operations.

- Food & Beverage Industry: Applied in the evaporation of juices, dairy products, and other heat-sensitive liquids, particularly in facilities with space and mobility constraints.

- Pharmaceuticals: Supports evaporation and pre-crystallization steps for active pharmaceutical ingredients, ensuring process flexibility and cleanroom adaptability.

- Industrial Wastewater Treatment: Offers a compact solution for reducing wastewater volume, particularly for remote sites, pilot operations, or industries with limited utility access.

Skid-Mounted Evaporator Models

| Model | Type | Capacity (Kg/h) | Energy Consumption (Kw.h) | Dimension (L*W*H) | MOC |

|---|---|---|---|---|---|

| SMC-50 | Concentration | 500 | 80–130 | 5.0*2.5*3.0 | TA2/2205/2507/316L |

| SMS-50 | Crystallization | 500 | 80–130 | 7.0*2.5*4.0 | TA2/2205/2507/316L |

| SMC-100 | Concentration | 1000 | 80–130 | 6.0*2.5*3.0 | TA2/2205/2507/316L |

| SMS-100 | Crystallization | 1000 | 80–130 | 7.5*2.5*4.0 | TA2/2205/2507/316L |

| SMC-200 | Concentration | 2000 | 80–125 | 8.5*2.5*3.5 | TA2/2205/2507/316L |

| SMS-200 | Crystallization | 2000 | 80–125 | 10.0*2.5*4.5 | TA2/2205/2507/316L |

| SMC-300 | Concentration | 3000 | 77–122 | 11.0*2.5*4.0 | TA2/2205/2507/316L |

| SMS-300 | Crystallization | 3000 | 77–122 | 12.5*2.5*5.5 | TA2/2205/2507/316L |

System Components

- Evaporator

- Separator

- MVR steam compressor

- Pumps, valves, and instrumentation

- Piping and structural frame

- PLC control system

- Solid-liquid separation section (for crystallization applications)

Why Choose Hydrodyna & Sanfeng?

As Sanfeng’s exclusive representative in Australia, Hydrodyna provides not only advanced equipment but also comprehensive local support, including system integration and after-sales service. Our collaboration ensures that clients receive tailored solutions backed by global expertise and local knowledge.