Crystallizer

Crystallizer – Advanced Solutions for Solid-Liquid Separation and Resource Recovery

Hydrodyna, in collaboration with Sanfeng, offers advanced crystallization systems designed to efficiently separate solids from liquids, facilitating resource recovery and waste minimization. These systems are integral to processes requiring high-purity crystal production and are adaptable to various industrial applications.

Key Features & Advantages

- High Purity Output: Produces crystals with minimal impurities, ensuring product quality for critical applications

- Energy Efficiency: Utilizes optimized thermal processes to reduce energy consumption during crystallization

- Versatile Applications: Suitable for a wide range of industries, including pharmaceuticals, chemicals, food processing, and wastewater treatment

- Scalable Design: Modular configurations allow for easy scaling to meet varying production capacities

- Automated Control Systems: Advanced controls ensure consistent operation and product quality

Applications

- Zero Liquid Discharge (ZLD) Systems: Facilitates solid-liquid separation by recovering salts and other crystallized solids from wastewater streams, helping achieve complete liquid elimination.

- Chemical Manufacturing: Used for the purification and crystallization of chemical compounds, enabling precise control over particle size and product purity.

- Mining & Metallurgy: Assists in the extraction and crystallization of valuable minerals and metals from leachate or process streams.

- Food & Beverage Industry: Applied in the production of crystalline food ingredients such as sugar and salt, where uniformity and quality are critical.

- Pharmaceuticals: Supports the controlled crystallization of active pharmaceutical ingredients (APIs) to meet stringent purity and consistency requirements.

Crystallization Methods

- Evaporation Crystallization – Removes part of the solvent through evaporation, leading to supersaturation and subsequent crystal formation.

- Vacuum Cooling Crystallization – Lowers the solution’s temperature under vacuum conditions to achieve supersaturation and initiate crystallization.

- Indirect Cooling Crystallization – Utilizes heat exchangers to cool the solution indirectly, promoting controlled crystal growth.

Crystallizer Types

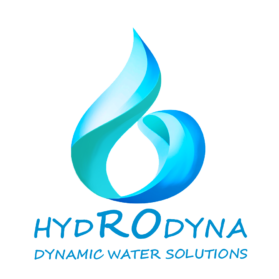

- OSLO Crystallizer – Promotes the growth of large, uniform crystals through a fluidized bed mechanism.

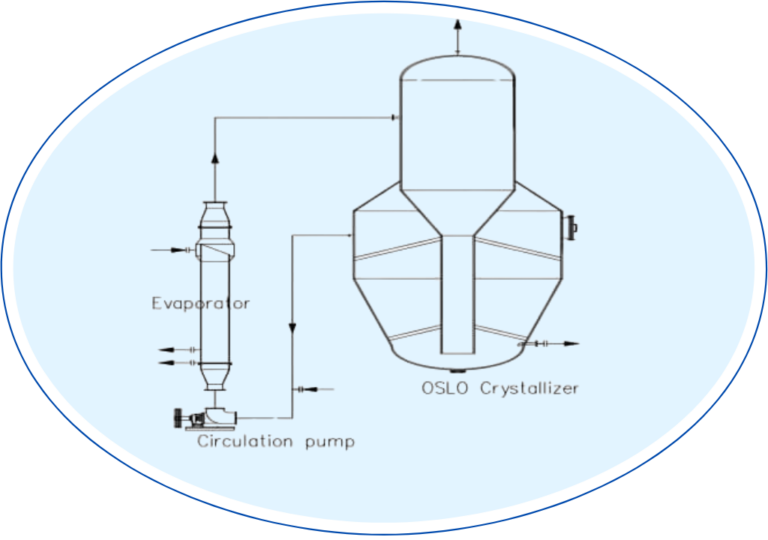

- DTB (Draft Tube Baffle) Crystallizer – Offers high production intensity and produces crystals with uniform size.

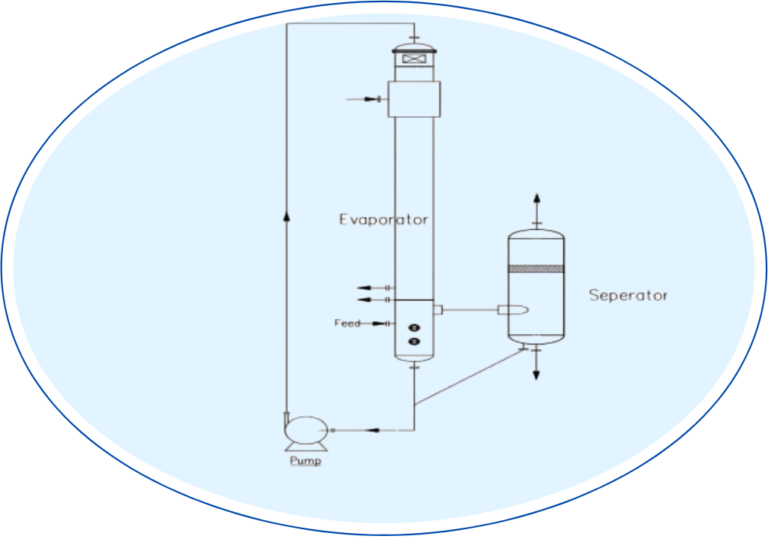

- FC (Forced Circulation) Crystallizer – Uses external circulation to handle large volumes, ideal for lower purity product requirements.

System Components

- Crystallization chamber

- Circulation pump

- Heat exchanger

- Separator

- Condenser

- Control system

Why Choose Hydrodyna & Sanfeng?

As Sanfeng’s exclusive representative in Australia, Hydrodyna provides not only advanced equipment but also comprehensive local support, including system integration and after-sales service. Our collaboration ensures that clients receive tailored solutions backed by global expertise and local knowledge.