What is an MBR?

Membrane Bioreactor (MBR) is an advanced wastewater treatment technology that combines biological treatment (typically activated sludge) with membrane filtration. MBRs offer a compact, high-efficiency solution for treating municipal and industrial wastewater, producing high-quality effluent suitable for reuse or safe discharge.

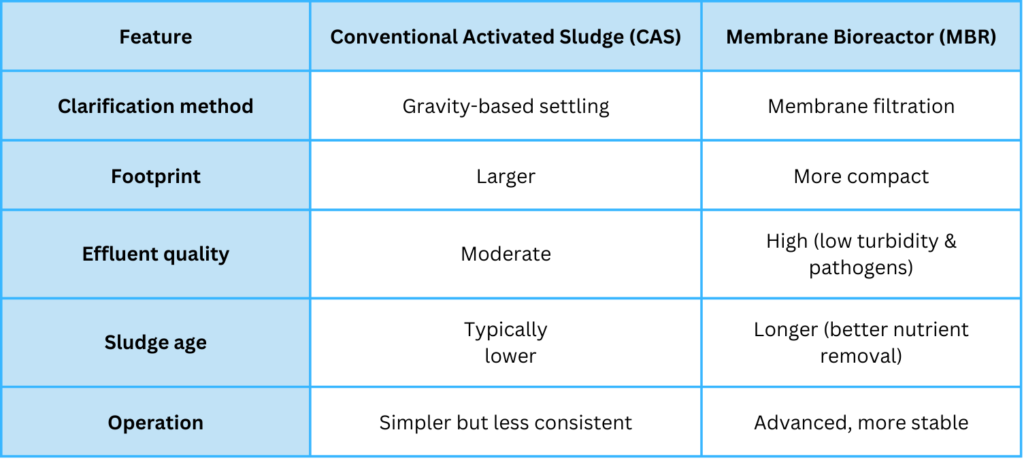

MBR vs Conventional Activated Sludge Process (CAS)

MBRs eliminate the need for secondary clarifiers and tertiary filtration, offering better process control and improved effluent quality.

Benefits of MBR Technology

- Consistently high effluent quality due to effective removal of BOD, nitrogen, and suspended solids.

MBR product water is suitable for water reuse applications and consistently meets Australia’s reclaimed water quality criteria for the protection of the environment, livestock, and human health. Typical MBR effluent contains <5 mg/L BOD, <1 mg/L TSS, and total nitrogen levels as low as 5–10 mg/L, depending on the design. These values align with Class A+ recycled water standards set by Australian guidelines, supporting safe use in irrigation, industrial applications, and non-potable urban reuse.

- Smaller plant footprint

MBR systems require 30–70% less footprint compared to Conventional Activated Sludge systems. This is due to the elimination of secondary clarifiers and higher biomass concentration in compact bioreactors (MLSS levels of 8,000–12,000 mg/L (or even higher), compared to 2,000–4,000 mg/L in CAS). The result is a more space-efficient and modular wastewater treatment solution

- Reduced sludge production

MBR systems typically produce 30–50% less excess sludge compared to CAS systems. This reduction is due to the higher sludge retention time (SRT) and complete biomass retention in MBRs, which promotes further biological degradation of organics and reduces biomass yield.

The main disadvantages of MBR systems are their higher operational complexity and the capital and operating costs associated with membrane cost. However, recent advancements in membrane technology and the entry of new manufacturers have significantly reduced both CAPEX and OPEX. As a result, MBRs are becoming increasingly cost-competitive and accessible for a wider range of applications.

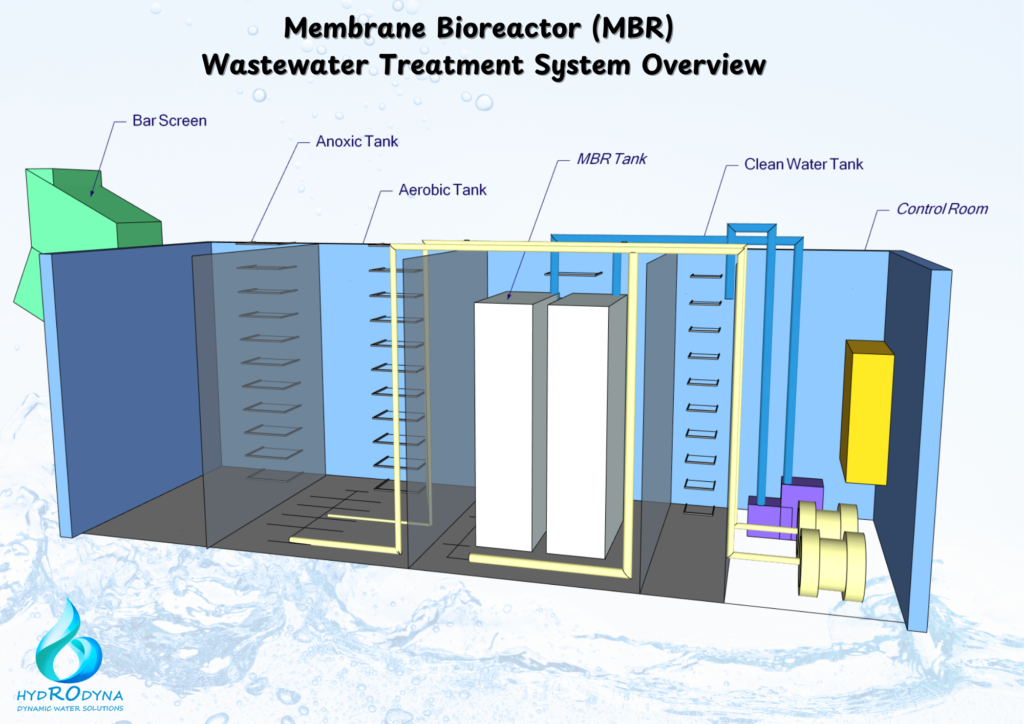

Key Process Steps in an MBR System

- Pre-treatment

Removal of coarse solids (e.g., screening and grit removal) to protect downstream membranes. - Equalization Tank

The flow is stabilized. - Anoxic Zone

Nitrate is converted to nitrogen gas through denitrification in oxygen-limited conditions. - Aerobic Zone

Organic matter is biologically degraded with the help of aerobic bacteria. Nitrification also occurs here. - Membrane Filtration

Mixed liquor is passed through semi-permeable membranes (with pore sizes of 0.01 to 0.4 microns) that physically retain suspended solids and microorganisms, producing clear, high-quality permeate. - Disinfectant

The filtered water is disinfected and discharged as clean water.

Applications of MBR Technology

MBR technology’s versatility makes it suitable for a wide range of applications, including:

- Municipal Wastewater Treatment: Treating sewage for cities and towns, ensuring compliance with environmental regulations.

- Industrial Wastewater: Managing wastewater from industries like food and beverage, pharmaceuticals, and manufacturing, where high-quality effluent is critical.

- Remote and Decentralized Systems: Providing reliable wastewater treatment for remote communities, resorts, or mining camps with limited infrastructure.

- Water Reuse Projects: Enabling the reuse of treated water for irrigation, industrial processes, or as a pre-treatment step for potable water production.

Membrane Bioreactor (MBR) System Configurations: Types and Design Variants

Each configuration offers specific benefits depending on the treatment requirements, space availability, and energy consumption goals. Understanding these options helps in selecting the most suitable MBR system for municipal, industrial, or commercial wastewater treatment applications.

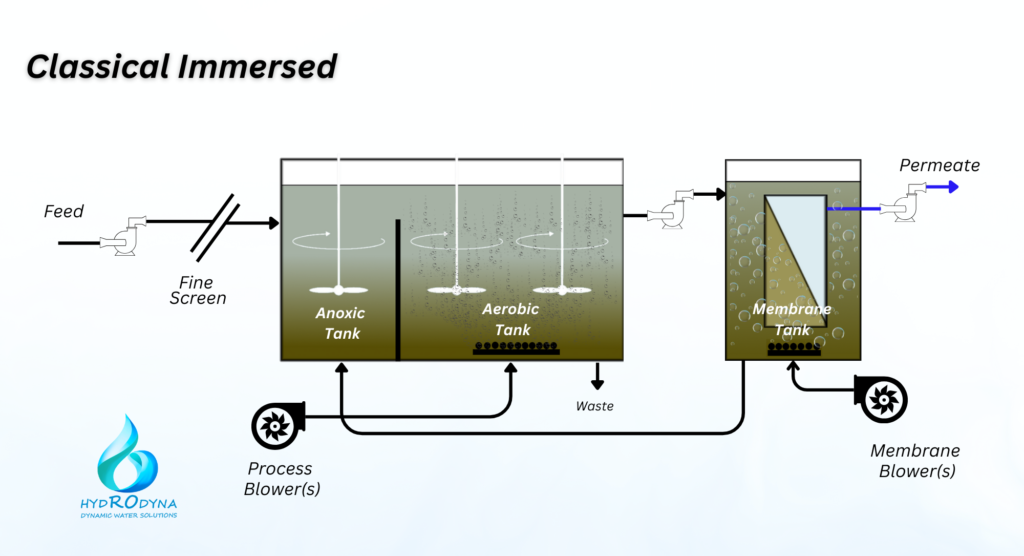

- Immersed MBR (i-MBR)

- Flat-sheet and hollow-fibre membranes are placed directly in the aeration or membrane tank.

- Suction or slight negative pressure is used to draw treated water through the membranes.

- Fine air bubbles are injected into the aeration tank to facilitate oxygen transfer, while coarse air bubbles are introduced into the membrane tank to scour the membrane surface.

- Immersed MBRs (iMBRs) are more energy-efficient than sidestream MBRs due to lower transmembrane pressure.

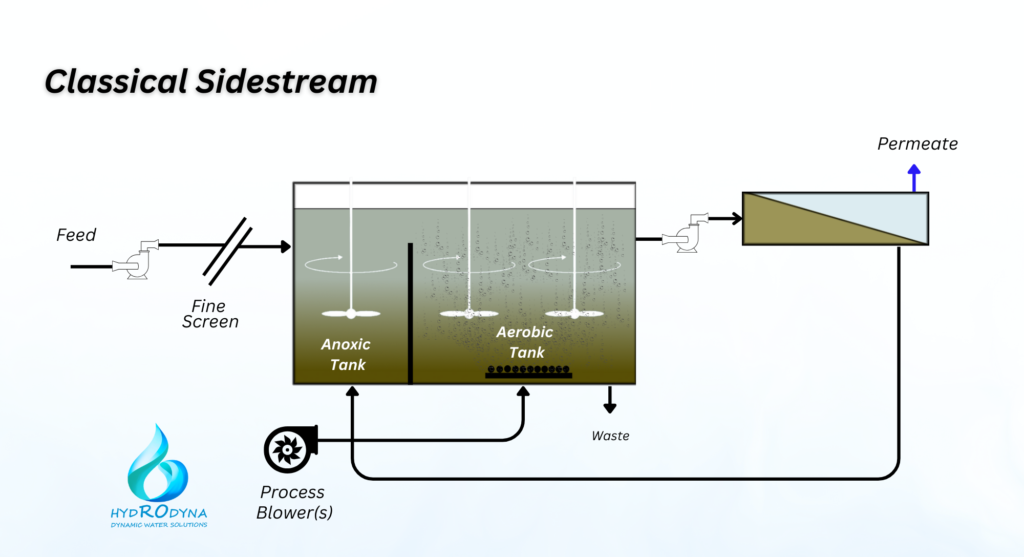

- Side-Stream MBR (s-MBR)

- Mixed liquor is pumped through external membrane modules.

- Offers easy membrane access for maintenance.

- Typically used in industrial applications with higher fouling loads.

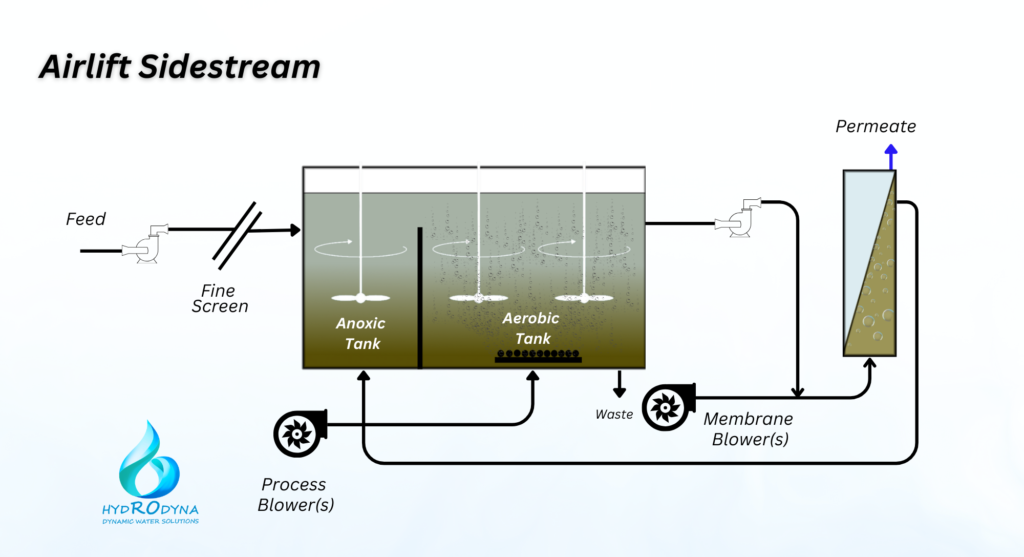

- Side-Stream with Airlift Configuration

- Similar to side-stream, but air is injected to assist circulation and reduce fouling.

- Reduces the need for high-pressure pumps and improves membrane lifespan.

References

Metcalf & Eddy – Wastewater Engineering: Treatment and Resource Recovery (5th Edition)

📖 Chapter 14: Membrane Biological Reactors

Membrane Biological Reactors – Edited by Faisal I. Hai, Kazuo Yamamoto, and Chung-Hak Lee

📖 Chapter 2: Process Fundamentals: From Conventional Biological Wastewater Treatment to MBR

Authors: V. Jegatheesan & C. Visvanathan

📖 Chapter 13: Commercial Technologies and Selected Case Studies

Author: Graeme Pearce

The MBR Book – Simon Judd

📖 Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment

A comprehensive guide covering MBR fundamentals, design, operation, and case studies.

At Hydrodyna, we support clients throughout the entire MBR journey — from technology selection and system design to plant upgrades and retrofits. We supply high-quality MBR membrane modules tailored to your application and provide hands-on operational training to ensure optimal performance and reliability. Whether you’re building a new system or enhancing an existing one, Hydrodyna is your trusted partner for efficient, sustainable MBR solutions.